Traditional PLCs have long been the backbone of industrial automation, but they come with significant limitations: high hardware costs, rigid scalability, complex maintenance, and vendor lock-in. Updating systems or adding new capabilities, AI for example, often means expensive hardware upgrades and downtime, while rolling out security patches across distributed devices is slow and risky. These challenges are particularly critical in real-time applications like robotics, motion, and CNC, where performance and jitter are essential.

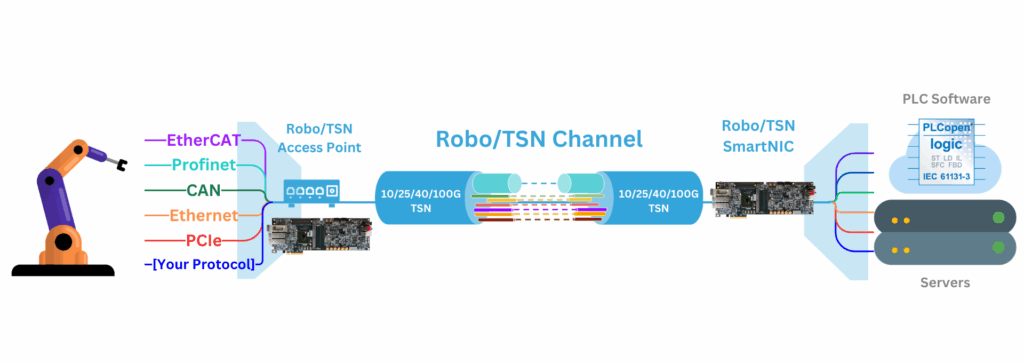

To overcome these barriers, MLE and CODESYS have been working together to deliver a virtual control system that shifts control from local PLCs to cloud or remote servers for easier scalability, faster updates, and secure real-time communication, even for data-intensive industrial workloads.

CODESYS virtual controllers bring flexibility with their software-based PLC system that eliminates the need for costly dedicated PLC hardware. They are easy to deploy, maintain, and update through its cloud-based, centralized PLC system, which allows rapid rollout of security patches and new features without downtime. Industrial users can manage coordinated motion and complex automation tasks with flexible, hardware-independent real-time control while using broad compatibility with fieldbus standards like EtherCAT and CANopen.

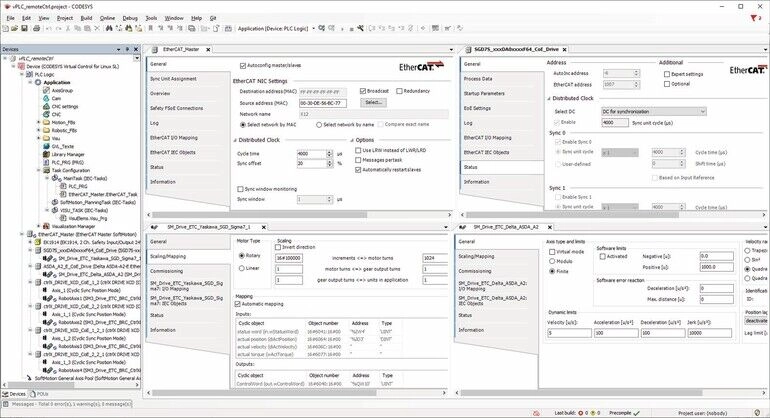

MLE Robo/TSN complements this capability by extending real-time, jitter-free communication between virtual controllers and distributed drives or I/Os over long distances. Using fiber optics and patented tunneling technology, Robo/TSN packetizes and transmits fieldbus data securely, fully compliant with IEC 62443 and compatible with functional safety protocols like FSoE and Profisafe, even in open IT networks. Most importantly, unlike other fiber optic systems, this data tunneling does not require any changes to existing PLC system configurations or operations. That enables CODESYS virtual controllers to maintain deterministic performance even when virtual controllers are hosted remotely.

The combination of CODESYS’ virtual control platforms and MLE’s Robo/TSN enable manufacturers to replace physical PLCs with secure, scalable virtual controllers hosted in datacenters, while maintaining high-performance, deterministic control for motion, CNC, and robotics tasks, even over distances exceeding 100 meters.

Key Benefits:

- Simplified system maintenance and faster security rollouts

- Reduced hardware complexity and costs

- Easy performance scalability for motion, CNC, and robotics applications

- Real-time, jitter-free control across extended distances (>100 m)

- Real-time data transmission from 1 Gbps to 100 Gbps

- Support for multiple protocols simultaneously (eg. PCIe, EtherCAT, Profinet, Ethernet, CAN, etc.)

This collaboration on virtual control technology paves the way for the next generation of resilient, secure, cost-efficient, and scalable industrial automation systems.

For more information, please visit:

- MLE Robo/TSN: www.mlecorp.com/robo-tsn/

- CODESYS web: www.codesys.com

About CODESYS Group

The CODESYS Group ranks among the world’s leading software manufacturers in the automation industry. The company´s main focus is the development and distribution of CODESYS, the well-known integrated IEC 61131-3 development environment (IDE) for controller applications and CODESYS Control, the platform independent runtime system.